Stacking Up with a Parametric Grasshopper

- Jax Whitham

- Mar 9, 2025

- 2 min read

Task 1: Parametric 3D Designs

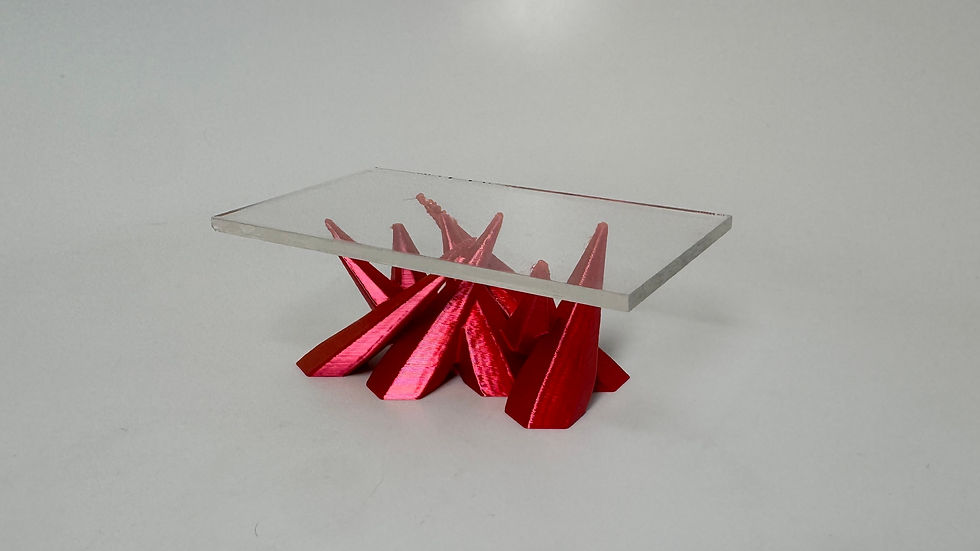

This parametrized shape is intended to convey a fluid whimsy feeling.

Starting from points and working up to a solid, parameterization begins with a closed curve composed from 11 grasshopper defined points. The x and y coordinates for these points have multipliers attached to them in addition to being individually manipulable. On the other flat size of the pointed curve is a circle with another variable center point, set at the origin of the XY plane, and an base radius to control relative size. The two curves formed so far a divided into points before being lofted. This division provides a gateway for curve resolution, or the number of points along the curve being used in construction of the solid. Shift list changes the position of the points inside the list, effectively changing the orientation of the base of the object. After lofting the two curves, a twist option gives manipulation power to the solid, maxing out at two complete revolutions.

In the Grasshopper file, changeable points are marked in purple, all other variable inputs are marked in red.

Task 2: Creating a 3D-to-2D Slicer

The slicer takes in a solid geometry from Rhino, in the images below one also produced in Grasshopper. The produced slices are determined by thickness of material to be used for fabrication. Marked in red is the slider input for material thickness.

Once slices are produced, they are laid out on the XY plane and labeled numerically.

Task 3: Slicer use and Fabrication

Overall fabricating was fairly straightforward. It would have been prudent to place a notch or similar indicator of alignment for aligning them

Main take away with fabrication has been: what the point of making a twist when you have to do it by hand anyway.

Grasshopper Files:

Comments